AOTO

World-class studio solutions for broadcast and cinema

Founded in 1993 in Shenzhen, China, and listed on the Shenzhen Stock Exchange in 2011, AOTO is a global leader in intelligent visual solutions and one of the first publicly listed companies in China’s LED industry, with over 30 years of extensive industry experience. The company specialises in virtual production studios, broadcast environments and LED cinema technologies, offering premium, customised solutions built on world-class LED display technologies.

In virtual production, AOTO has delivered over 80 large-scale studios worldwide, capturing 33% of the global market share. These are used across film, advertising, gaming and live broadcast, with trusted partnerships established with top Fortune 500 companies including Tencent, NVIDIA, Meta and AWS.

In broadcast, AOTO has built over 30 advanced TV studios for major networks such as CCTV, CNN, BBC and TBS. While in cinema, AOTO has partnered with a leading Chinese film group to drive LED innovation, offering multiple DCI-certified products and introducing the world’s first HDR-certified LED cinema system, ‘CINITY LED’, ranking No.1 globally in LED cinema screen market share.

Core Areas of Expertise

- Virtual Production Solutions (VP/XR)

- TV Studio Solutions (Broadcast)

- LED Cinema Solutions

- Smart LED solutions for Rental, DOOH, Sport and Commercial Display

Key Products/Brands

Virtual Production Solutions (VP/XR)

RM Series (LED Display Panel)

Pixel Pitch: 1.56mm/1.95mm/2.31mm

The RM series is a star product specially designed for virtual production and XR studios. With an intelligent product design, it features 1/6 lowest scanning mode in the premium offer, 7680Hz refresh rate, 99.9% DCI-P3 colour gamut and low reflectivity, effectively reducing the effect of other disturbing light.

SW (RGBW ) Series (Ceiling Display)

Pixel Pitch: 5.76mm

SW(RGBW) series can achieve dual-mode switching for virtual production, highly replicating natural light. Combined with 360° full-view technology, it supports multi-directional lighting, ensuring no colour bias when viewed from any angle. The unique design structure, combining the two special knobs and connecting pole, enhances the safety of installation. Features include:

- CRI and TLC≥90

- 7680Hz refresh rate

- Magnetic Front Maintenance

- Dual Mode: Fill Light Mode and RGBW Mode

AE Series(Floor Display)

Pixel Pitch: 2.31mm /1.56mm

The new generation, AE series of floor display is designed for XR Studio applications, allowing creators to create more dreamy and creative spaces. The viewing angle of AE series can be up to 180 degrees in both vertical and horizontal planes, and the image can have superb colour consistency with no colour cast. This allows for optimal picture quality to be captured on camera in the studio. Features include:

- Super Load Capacity (2 tons/㎡)

- AOTO Full Viewing Angle Technology

- High Protection

- High Precision Splicing

- Floor Installation

TV Studio (Broadcast Products)

CLD Series ( Mini LED )

Pixel Pitch: 0.9375mm/1.25mm/1.5625mm

The newly innovated AOTO Mini LED Series is characterised by smaller LED chips, more robust LED panels, greater air tightness and better optical design. It has solved the fragile problems of fine pixel LED products, unable to be repaired on-site and the inconsistency of surface black colour of COB products. AOTO Mini LED products have obtained over 30 patents worldwide.

CV Series

Pixel Pitch: 0.9375mm/1.25mm/1.5625mm/1.875mm/2.5mm

The CV series is characterised by smaller LED chips, more stable screen robustness and better sealing and optical design. Multiple packaging options can be selected to better satisfy different application scenarios.

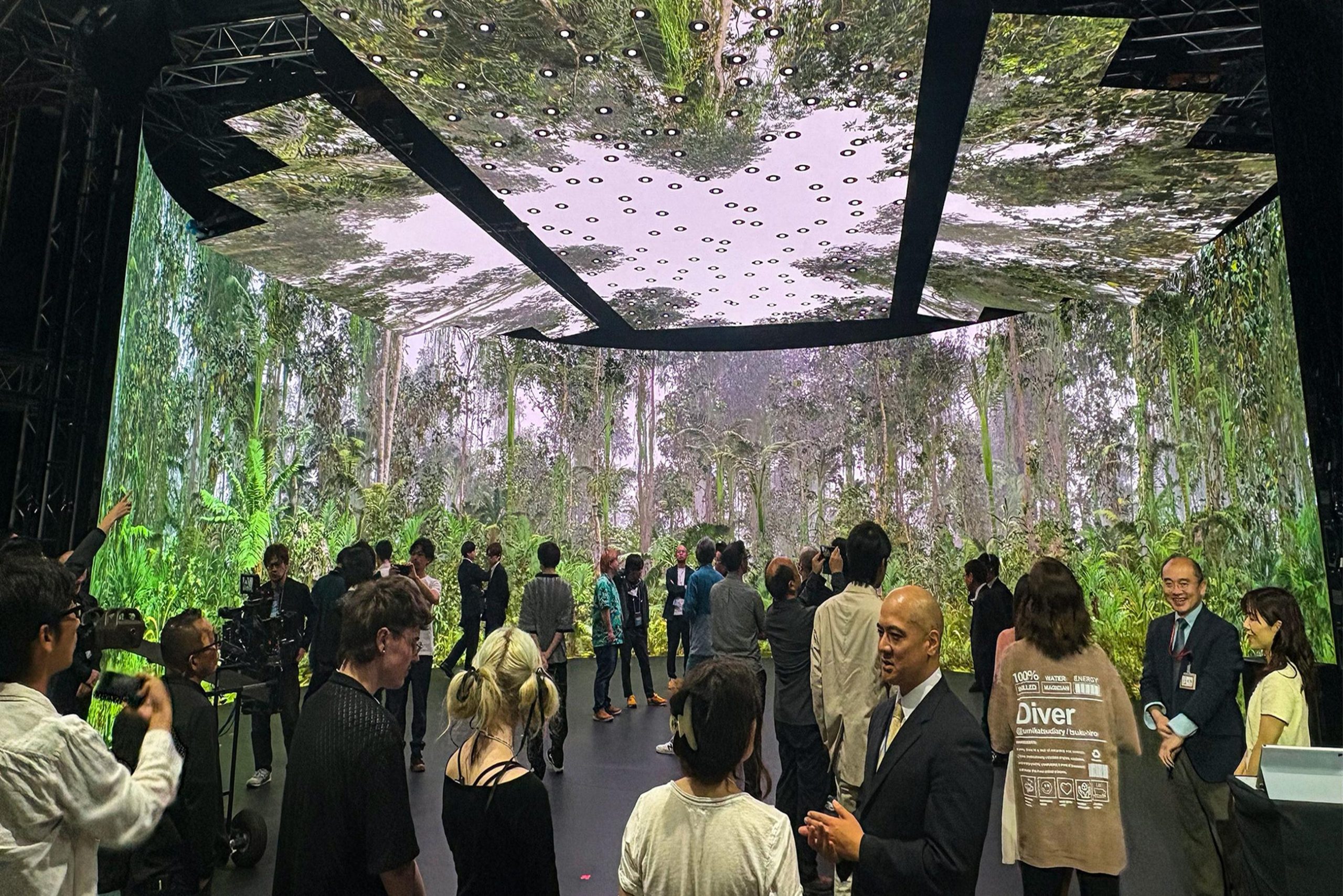

Toei Unveils Japan’s Largest LED Virtual Production Studio, Powered by AOTO

Tokyo, May 22, 2025 – Japan’s entertainment giant Toei has officially unveiled its state-of-the-art VP studio in Tokyo, marking a major milestone for the country’s digital content industry. Designed and built in close collaboration with global visual solutions leader AOTO, the Toei VP Studio is now the largest LED-based virtual production facility in Japan—and the first to be fully operated by a Japanese film studio.

Spanning 640 sqm, the studio’s standout feature is its immersive 270-degree curved LED volume, built with AOTO’s RM1.5 series for the main wall and MXH panels for the ceiling. The setup includes:

- LED Wall: 30m × 5m, 600 LED panels, P1.56mm

- Ceiling: 11m × 10m, 236 panels, P3.75mm

- Performance: 7680Hz refresh rate, DCI-P3 color gamut, 6000 nits peak brightness, 170°+ viewing angle

These specifications ensure seamless in-camera VFX (ICVFX) rendering with crystal-clear visual fidelity and minimal post-production workload. Integrated with Disguise media servers, Brompton Technology processors, Mo-sys tracking, and ARRI ALEXA 35 camera systems, Toei VP Studio offers a fully integrated and globally competitive VP pipeline.

“This is more than a facility—it’s a turning point for Japan’s film production model,” said a Toei representative. “We’re empowering our creators with tools that eliminate boundaries between imagination and execution.”

Shaping a New Production Paradigm in Japan

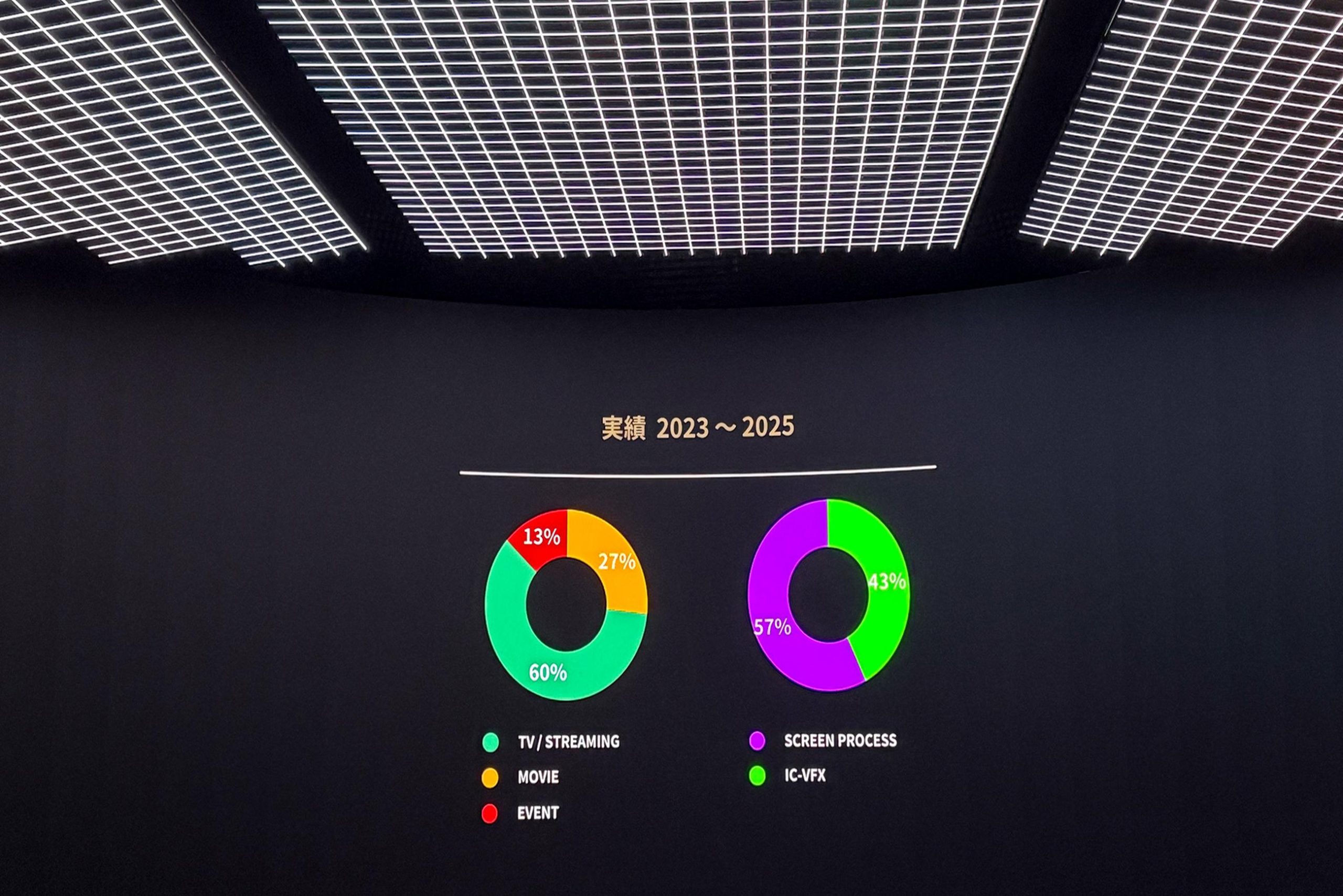

According to Toei, the studio will serve a diverse content mix from 2023 to 2025:

- 60% TV and streaming productions

- 27% film

- 13% live events and hybrid productions

- 57% of all productions expected to use In-Camera VFX workflows

The studio also features multilingual collaboration support and international-standard pipelines, positioning it as a hub for global co-productions and cross-border creative projects.

AOTO: From Gotham City to Tokyo

The industry has long recognized AOTO‘s innovation in virtual production. From the neon-lit streets of Gotham in the Hollywood blockbuster The Batman to the intense aerial scenes in Apple TV+’s Masters of the Air, AOTO’s technology has helped deliver some of the most ambitious storytelling environments in modern cinema. Its LED VP Solutions are trusted by global leaders such as NVIDIA, Meta, Amazon AWS, Microsoft, Google, Tencent, China Film Group, and XON Studios in South Korea.

With a vertically integrated solution—from R&D to manufacturing and deployment—AOTO delivered full-stack technical services for Toei, including precision engineering, real-time color management, and 24/7 remote diagnostics. The installation achieves millimeter-level alignment through proprietary calibration methods, ensuring unmatched visual uniformity.

A Regional Milestone in Virtual Production

The Toei VP Studio is not only a technical feat—it is a symbol of Asia’s growing self-reliance in cinematic innovation. By building a domestic, studio-operated VP hub, Japan is paving the way for a more agile, efficient, and scalable production ecosystem.

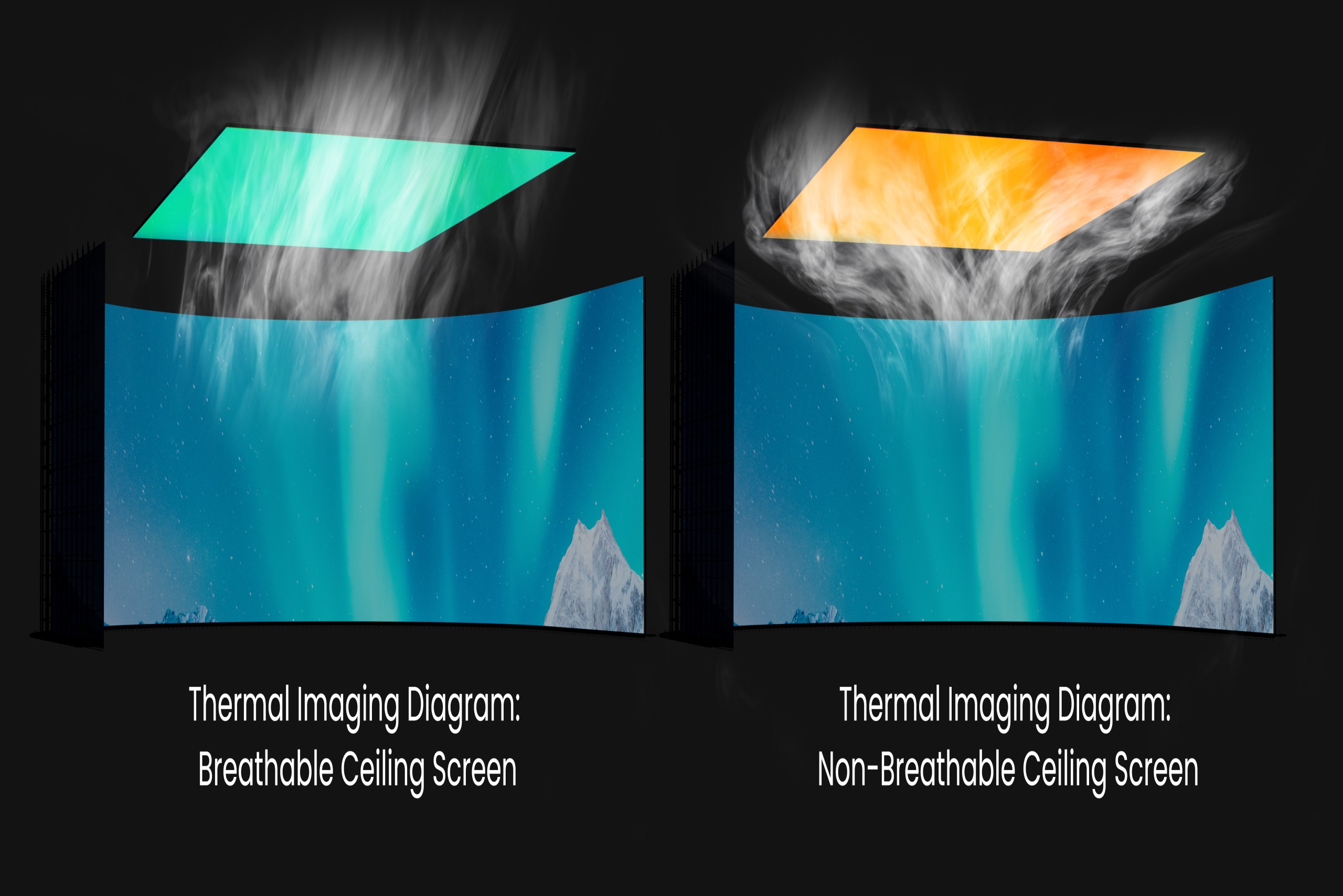

Breathable and Lightproof: AOTO’s SW Series Ceiling Screens Tackle the ‘Heat Dome’ Challenge

In virtual production systems, high-brightness LED wall displays can accumulate significant heat during extended operation due to their large surface area. Traditional ceiling screens often feature enclosed structures, making it difficult for this heat to dissipate efficiently. If the architectural floor-to-ceiling height of the shooting environment is insufficient, the natural upward flow of hot air and convective cooling will be restricted, further exacerbating heat buildup near the ceiling displays.

This sustained high-temperature environment poses a serious threat to LED ceiling screens. It can accelerate LED aging, intensify brightness decay, cause color coordinate shifts, and lead to output instability and reduced color consistency. Additionally, it significantly increases the risk of LED failure (dead pixels) and thermal malfunction of driver ICs and other electronic components.

These issues directly compromise the image quality and color fidelity essential for virtual production, increase maintenance costs, and may even lead to production interruptions.

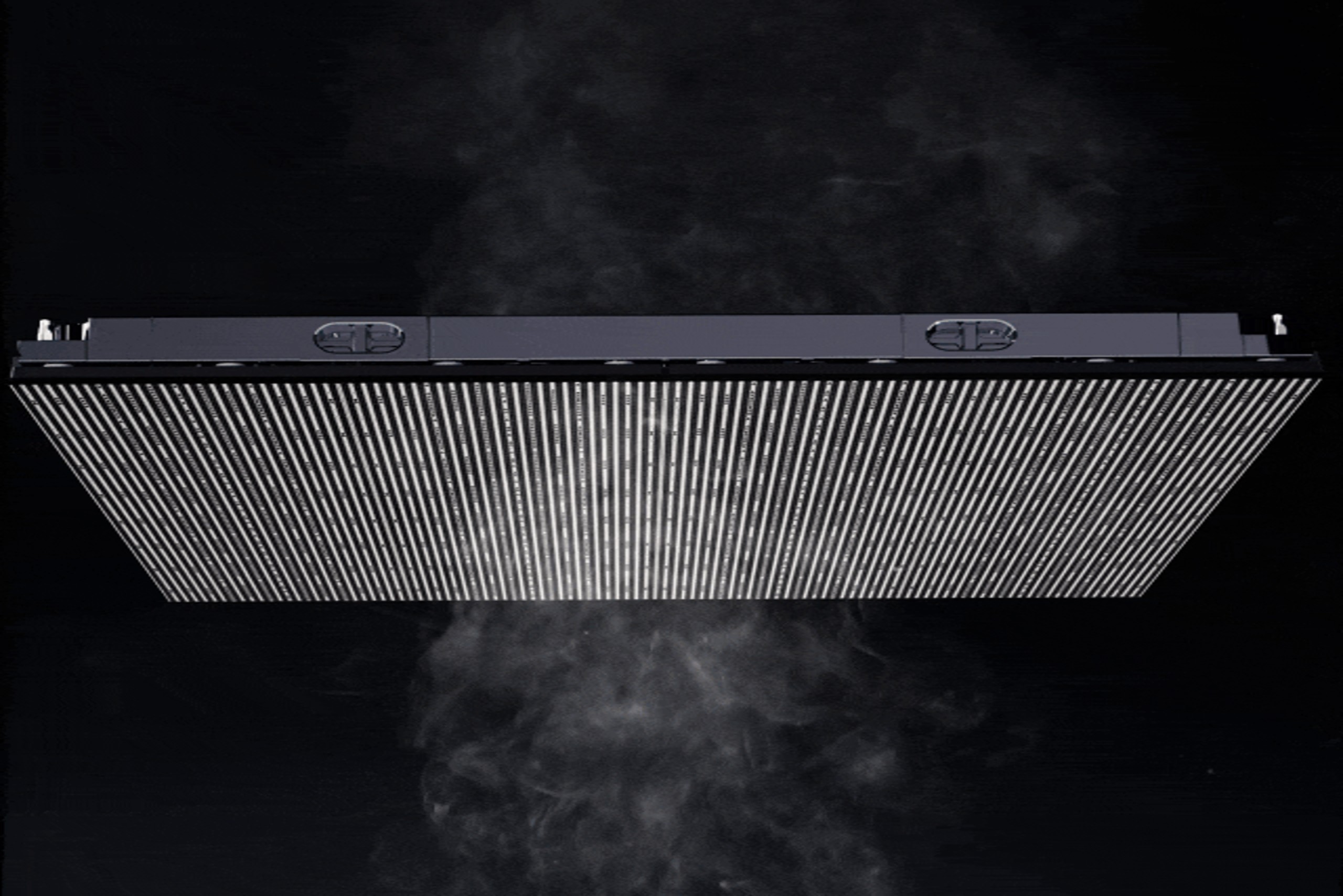

Structural Breakthrough in Breathable and Lightproof Design

Unlike traditional approaches that achieve heat exchange by adding perforations or hollowing out structural elements, the SW Series does not compromise optical light-blocking performance in exchange for airflow pathways. In virtual production environments, ceiling screens serve as the reflective surface for overhead key lighting and therefore must possess excellent light-shielding capabilities. A purely “breathable” design often disrupts optical enclosure integrity, resulting in light leakage from the rear, exposure of internal structures, and increased risk of breaking the visual illusion. These issues can interfere with light reflection control and undermine the consistency and clarity of the captured image.

To address this, AOTO’s SW Series Ceiling Screen achieves a breakthrough “breathable and lightproof” technical approach, successfully striking a precise balance between “permeability” and “containment.” The solution employs a dual-path collaborative design:

At the thermodynamic level, the internal topology of the SW screen modules is restructured. Low-resistance thermal channels are strategically embedded within individual LED cabinets or between module junctions. These channels enable natural air penetration through the screen, driven by thermal pressure differentials—from high-temperature zones at the bottom to lower-temperature zones at the top—thereby enabling efficient passive cooling.

At the optical level, light-blocking composite materials are seamlessly integrated to eliminate rear light interference, ensuring the visual integrity of the front-facing image during shooting.

This design not only ensures the light-blocking capability and imaging stability of the SW ceiling screen, but also achieves efficient heat dissipation in a restrained and concealed manner, without relying on traditional perforations or added materials, effectively preserving the structural integrity and visual purity of the screen, truly balancing performance and aesthetics.

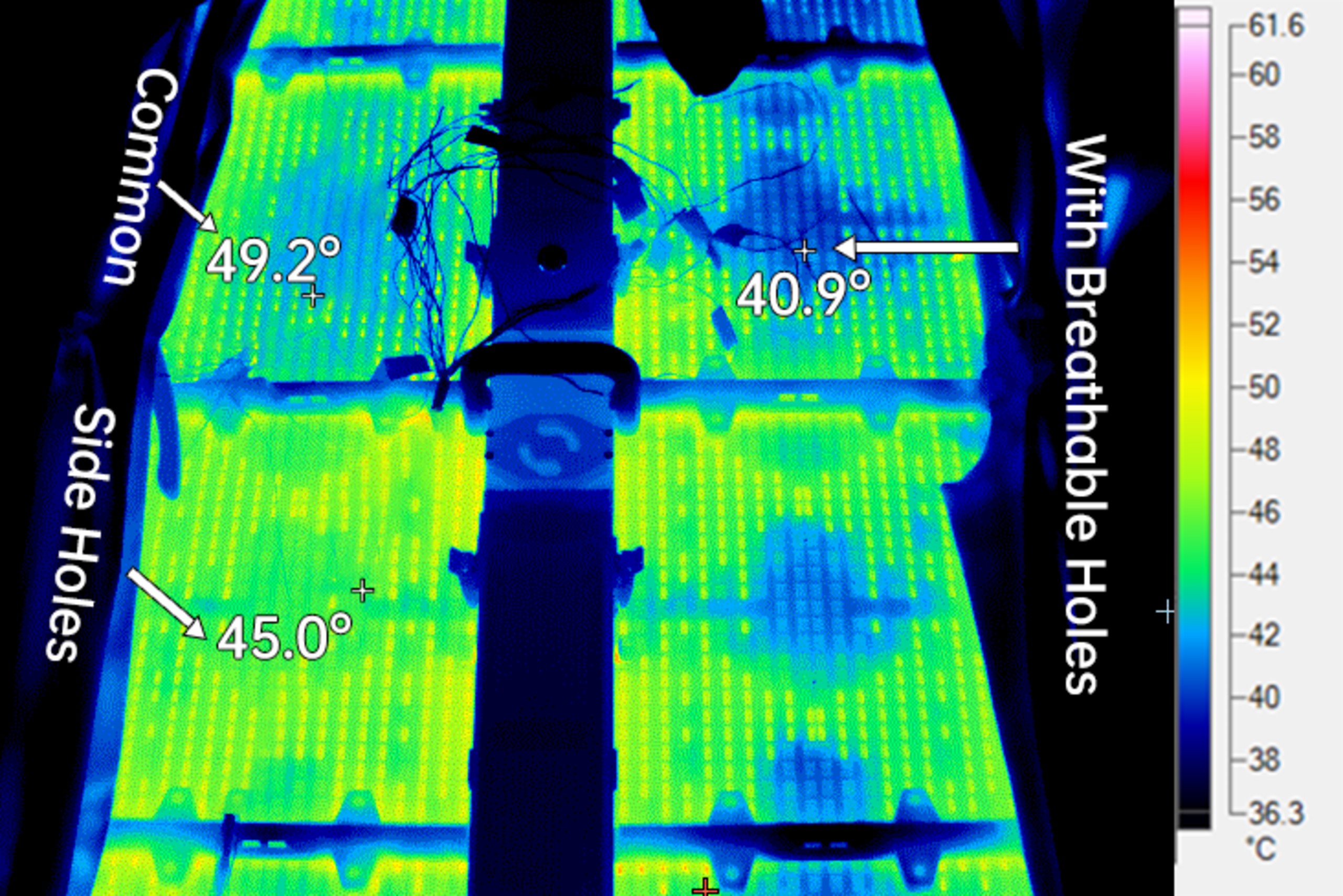

SW Ceiling Screen Heat Dissipation: Experimental Validation and Results

AOTO conducted rigorous laboratory testing and real-world application verification to quantitatively evaluate the thermal performance of the breathable structure used in the SW ceiling screen. Test data showed that under the same thermal load conditions, the front surface operating temperature of the ultra-large screen using this structure was significantly reduced by 8°C to 10°C. This result directly confirms that hot air is effectively discharged from the front area of the screen, fundamentally improving the operating environment of the core display components, which is beneficial for enhancing the long-term stability and lifespan of the LED elements.

At the same time, monitoring data indicated a noticeable downward trend in the temperatures of internal components such as PCBs and heat dissipation substrates. This demonstrates that not only is the accumulated hot air on the exterior being vented, but the heat generated internally by the screen during operation is also being more effectively dissipated due to internal airflow.

Crucially, temperature monitoring of the suspended area behind the ceiling screen showed an increase of approximately 5°C. This phenomenon provides direct evidence that hot air successfully penetrated the airflow channels within the screen and was released into the rear space, strongly validating both the unobstructed airflow design and the overall effectiveness of the thermal management mechanism.

Multidimensional Enhancement of Equipment Performance and Operational Efficiency

AOTO Electronics’ self-developed breathable SW Sky Screen heat dissipation structure, based on precision engineering design and material innovation, provides a systematic solution to the challenge of thermal accumulation encountered in virtual production scenarios, comprehensively enhancing the operational performance and applicability breadth of virtual studio systems.

Firstly, by optimizing airflow channels and heat dispersion pathways, this structure effectively suppresses the temperature rise of display modules during operation, reducing the probability of hardware failures induced by high temperatures (such as dead pixels and driver abnormalities). This significantly enhances system stability and reliability, providing solid support for the continuity and controllability of shooting schedules.

Secondly, regarding image output, the stable thermal management mechanism helps maintain color consistency and brightness uniformity of the LED screen under high-load operation. This ensures that imaging quality does not suffer from color shift or attenuation due to thermal runaway, thereby reducing post-production correction costs and elevating the professional standard of visual presentation.

Furthermore, the structural heat dissipation design effectively delays the thermal aging process of core components, extending the overall equipment lifespan. This indirectly reduces the depreciation rate and the frequency of maintenance and replacement, offering quantifiable benefits for production units in controlling long-term asset operating costs.

Simultaneously, this technology enhances the system’s spatial adaptability flexibility. It enables virtual production technology to overcome previous limitations regarding venue height and ventilation conditions, making it suitable for more scenarios and broadening application boundaries.

Finally, leveraging an efficient passive cooling strategy, this solution significantly reduces reliance on active cooling equipment (such as high-power air conditioning). This not only decreases system energy consumption but also optimizes the complexity and cost structure of cooling configurations, aligning with the industry trend towards green filming and energy conservation/carbon reduction.

As one of the earliest companies to introduce LED-based virtual production solutions, AOTO Electronics has participated in the construction of over 100 large-scale virtual studios both domestically and internationally. It has provided film production solutions for numerous Fortune 500 companies including Tencent, Apple, Microsoft, Netflix, Amazon, Meta, and Japan’s Toei. Where technology is captivating, AOTO Electronics is committed to collaborating with global creative teams to drive the continuous advancement of film production technology, unleashing new creative possibilities for the industry.

AOTO and CBIC Co-Host CITS 2025 at BIRTV Expo, Spotlight Future of Virtual Production

Beijing, China – July 23, 2025 — Co-hosted by AOTO and the China Broadcasting International Corporation (CBIC), the Cinematech Innovation & Trends Summit 2025 (CITS 2025) took place at the Hilton Beijing Hotel as part of the official BIRTV2025 program.

Over 150 professionals from the film, broadcasting, and technology sectors (including representatives from China Film Group, iQIYI, Aputure, G-Ka, and Beijing Film Academy) gathered to explore how emerging tools are reshaping the way stories are told.

In his opening address, Wu Hanqu, Founder of AOTO, highlighted the rapid global adoption of LED-based virtual production:

“In the past year alone, nearly 100 LED stages have been built worldwide, and over 200 major films have adopted virtual workflows. We’re entering an era where physical and digital worlds merge to co-create stories. At AOTO, we aim to lead this evolution through continuous innovation and collaboration.”

Global Perspective: Noah Kadner on Real-Time Production

A major highlight of CITS 2025 was the keynote speech by Noah Kadner, Editor at American Cinematographer and author of The Virtual Production Field Guide. Known for his deep insights into LED volume workflows and Unreal Engine pipelines, Kadner offered a global perspective on how real-time tools are transforming every stage of production.

Kadner explained: “Virtual production isn’t merely a technological upgrade; it represents a fundamental shift in mindset. Filmmakers are moving key decisions earlier into previsualization. Real-time lighting, environment builds, and performance capture are enabling more flexible, collaborative, and visually cohesive productions.”

He also discussed how virtual production is becoming more accessible across budget levels—from indie shorts to blockbuster features—and emphasized the need for standardized workflows to support broader adoption. His case studies included LED stage use in episodic content, hybrid location/volume shoots, and the growing influence of AI in generating and iterating visual assets.

“The future of virtual production is all about accessibility and modularity,” Kadner concluded. “What used to take weeks can now happen in real time, on-camera, with the entire creative team engaged in the process.”

Industry Voices: AI, XR, and LED Innovation

A diverse group of experts shared insights on how emerging technologies are redefining content creation:

- Wu Wei, Vice Chairman & VP at AOTO, presented XR use cases in livestream commerce, education, and training—emphasizing the adaptability of AOTO’s LED systems.

- Ma Ping, Vice President of the China Society of Cinematographers (CNSC), showcased AI-driven content generation and the shift toward algorithm-assisted creative workflows.

- Bian Wei, Executive Director of China Film Technology and General Manager of CINITY, shared that CINITY LED theaters accounted for 26.79% of this year’s Spring Festival box office and are expanding into esports and live events.

- Zhao Jianjun, Professor at Beijing Film Academy, addressed challenges in LED-based production such as moiré effects, color accuracy, and camera synchronization. He emphasized the value of academic-industry collaboration.

Closing Roundtable: Standards, Skills, and Scalability

A closing roundtable moderated by Ma Ping addressed key challenges including standardization, talent development, and the integration of creative and technical workflows.

Panelists included leaders from AOTO, G-Ka Robotics, iQIYI, the Royal Canadian Film School, and Aputure. The group emphasized building a new generation of professionals skilled in both storytelling and real-time production technologies.

About CITS 2025

The Cinematech Innovation & Trends Summit (CITS 2025) is a flagship event under BIRTV2025, co-hosted by CBIC and AOTO Electronics. The summit explores innovations in virtual production, AI-driven workflows, XR applications, and LED technology—connecting global creators and technologists shaping the future of media.

Key Projects

VP/XR Studios

- NVIDIA XR Studio

- Tencent CDD VP Studio

- The Batman Studio

- Apple TV Masters of the Air Studio

- Toei Studios

Broadcast Studios

- MBC Studios

- Al Jazeera News Studio

- MTV News Studio

- Asharq News Studio

- Beirut TV

- Abu Dhabi TV Studio

Key Clients

Middle East: MBC, Al Jazeera, MTV, Bloomberg, Asharq, MBN

Global: NVIDIA, Meta, Amazon, Toei (Japan), Apple, Tencent, CCTV, BBC, CNN, TBS

Global Headquarters

9- 10F, High-tech Zone Union Tower

No. 63, Xuefu Road

Nanshan District, Shenzhen, China

www.aoto.com